Business area

Learn how major industries use digital manufacturing to shorten development time, reduce production costs, and push products with better products at an unprecedented speed To the market.

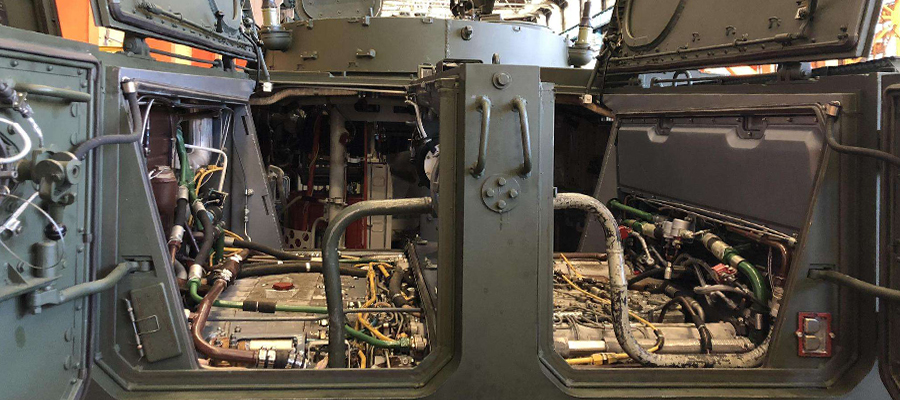

Military industry

From the reinforcement of computers to the large-scale personalization of military products, digital manufacturing accelerates the development of the military industry through CNC machining and die-casting, and high-quality and high-precision machining requires production.

Aviation field

From early prototyping and design verification to thermal testing and launch, our automated manufacturing services are often used for fully functional aerospace components.

Medical field

From connected devices to large-scale personalization of medical products, digital manufacturing accelerates medical development through rapid prototyping, bridging tools, and small batch production.

Consumer Electronics Field

Support more SKUs and product customization that consumers now expect by manufacturing custom prototypes and end-use production parts on demand.

![]()

Other areas

While meeting the growing needs of social development, it is still possible to support traditional equipment and machinery by manufacturing customized parts on demand.

Reduce the weight of military product parts

Accelerate the time-to-market of medical products

Data resources

CNC precision military parts

Machining aviation parts customization

Medical physiotherapy equipment accessories parts