Customer-supplied materials

If you want to provide materials for manufacturing parts, please fill out the form below and upload two required documents. After processing your information, we will continue to provide shipping information and material ID numbers. If you provide metal materials, please note that we only accept magnesium alloy, aluminum alloy, and stainless steel packaging materials.

Green Bat Material Guide

Materials

| Materials | Maximum size |

|---|---|

| AZ91D | 1100mm x 800mm x 500mm |

| ZK61 | 1100mm x 800mm x 500mm |

| AZ31 | 1100mm x 800mm x 500mm |

| AZ61 | 1100mm x 800mm x 500mm |

| AM60 | 1100mm x 800mm x 500mm |

| Other materials | 1100mm x 800mm x 500mm |

| Customer provides materials | 1100mm x 800mm x 500mm |

* This table is adapted from www.www.www-49829.cn.

|

Materials |

Minimum size |

|---|---|

| AZ91D | 10mm x 20mm x20mm |

| ZK61 | 10mm x 20mm x20mm |

| AZ31 | 10mm x 20mm x20mm |

| AZ61 | 10mm x 20mm x20mm |

| AM60 | 10mm x 20mm x20mm |

| Other materials | 10mm x 20mm x20mm |

| Customer provides materials | 10mm x 20mm x20mm |

* This table is adapted from www.www.www-49829.cn.

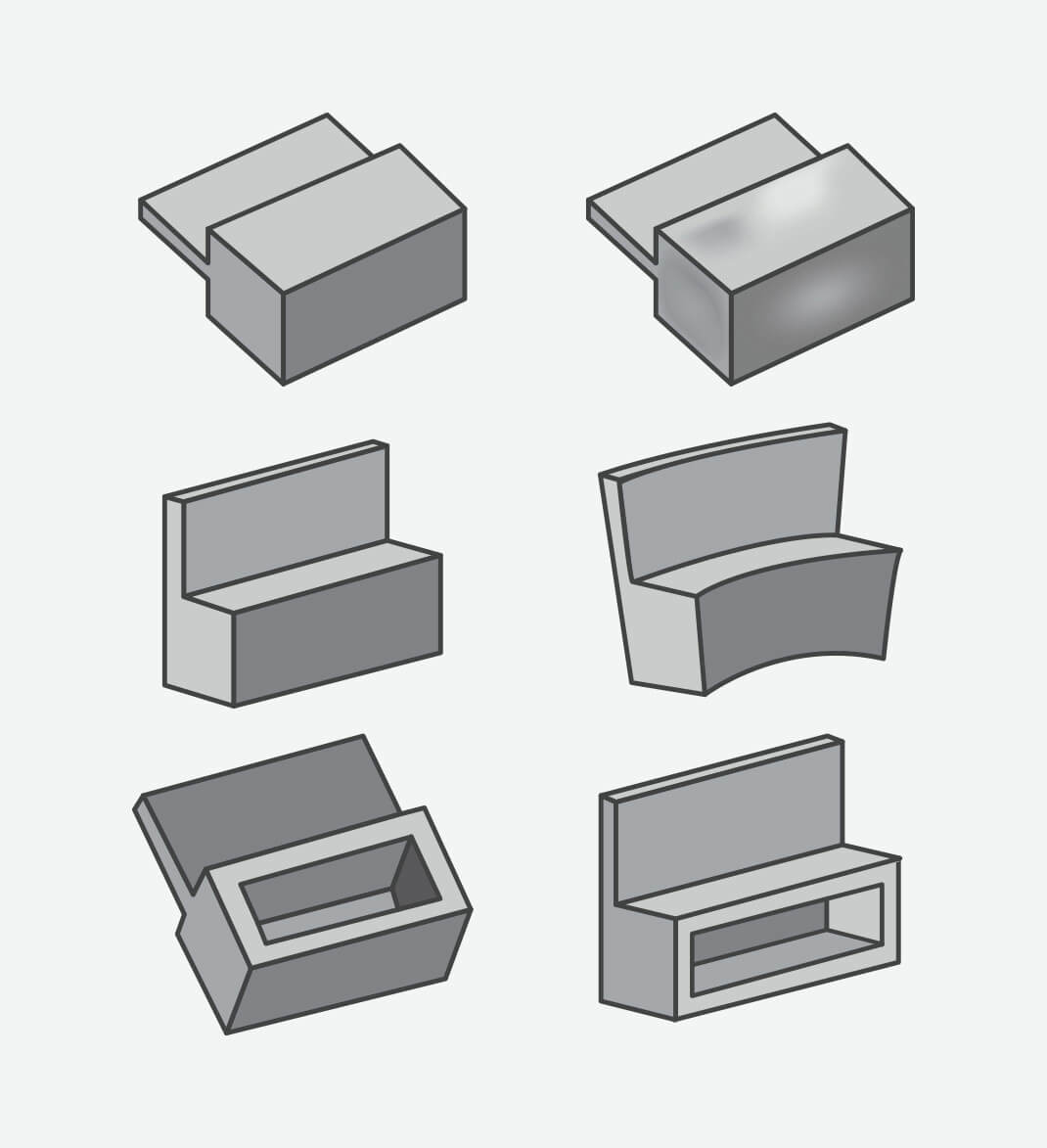

The first line: parts with thicker features, and the resulting sink after molding. Middle row: Designed as a part with thicker features.

Bottom: Thicker features make it easier to make molded parts.